Crown module全自动生产线

优点介绍

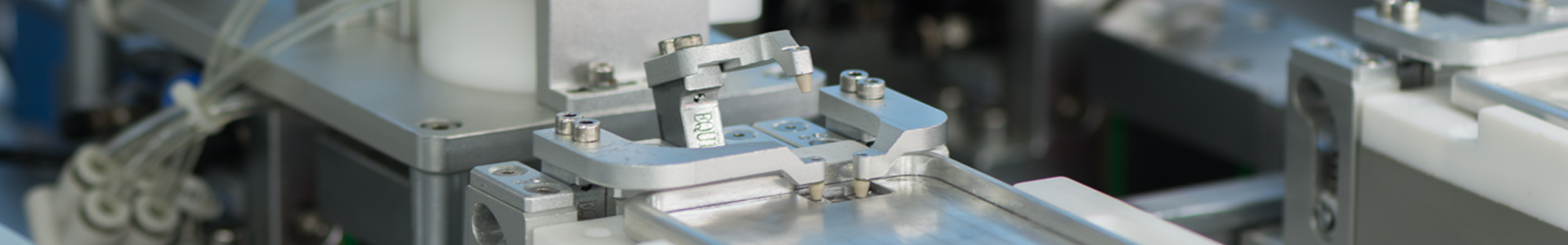

平皮带流水线,输送装入未组合的旋钮配件的载具。在组装机流水线定位载具,料仓模组自动上料,机械手从载具中取出旋钮配件,利用CCD旋钮配件位置。4pcs CCD定位旋钮配件位置,将3种不同的配件装入焊接平台,三分割转盘将焊接平台送至焊接位置,龙门调节模组通过CCD调整配件位置及间隙,激光焊接机将配件焊接在一起。整线包含自动上料、点导电膏、组装+激光焊接、2D检测、自动下料等工站

Flat belt conveyor transfers carriers with crown module components. Conveyors positioning carriers in assembly station, auto loading and robot picking up to be assembled components with the alignment of 4 sets of CCD to load three components to welding platform. Then rotatory module moves welding platform to welding position for laser welding by gantry adjusts position and gap.The whole line involves auto loading and unloading, conductive paste, assembly, laser welding, 2D inspection, etc.

参数配置

采用500万像素CCD进行配件定位和扫码,以及1000万像素CCD捕捉配件位置及间隙采用 精密模组,精度0.02mm

CCD可进行图像比对,并且带有AOI 检测功能

采用激光焊接机进行旋钮焊接

CCD*56套/整线

整线物料使用达到1000级无尘要求

双组装工位并且单工位可做双工位的功能

机械手12台/整线

70轴/整线

设备精度:±0.03mm

UPH:1200

Using a 5-megapixel CCD for components positioning and scanning as well as a 10 megapixel CCD to capture components positions and gaps

Using precision modules with an accuracy of 0.02mm

CCD can perform image comparison and has AOI function

Using a laser welding machine for crown module welding

CCD * 56 sets/full line

The usage of materials on the full line meets Class 1000 cleanroom requirement

Dual assembly stations and single station can perform dual station functions

12 robot /full line

70 axes/full line

Equipment accuracy: ± 0.03mm

UPH: 1200

功能描述

将旋钮配件组合、点胶、焊接、检测等多功能Multi function assembly of crown module including dispensing, welding, testing, etc