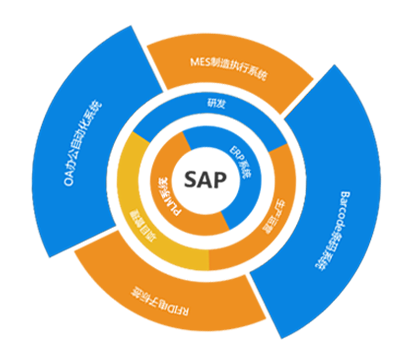

Secote is equipped with a Tier 3 server room and has implemented SAP to help manage its business, using modules in the areas of project management, R&D, assembly, manufacturing, and materials management. Our PLM system facilitates the direct integration of R&D and ERP. Secote has developed and implemented the Manufacturing Execution System (MES), Barcode System, Radio Frequency Identification Devices, and Weaver OA for in-depth integration of management and information.

Secote is equipped with a Tier 3 server room and has implemented SAP to help manage its business, using modules in the areas of project management, R&D, assembly, manufacturing, and materials management. Our PLM system facilitates the direct integration of R&D and ERP. Secote has developed and implemented the Manufacturing Execution System (MES), Barcode System, Radio Frequency Identification Devices, and Weaver OA for in-depth integration of management and information.

Professional management system

Professional management system

Projects Monitoring In Real-time

Projects Monitoring In Real-time

English Speaking Working Environment

English Speaking Working Environment

Information management

Information management

Secote uses a strong matrix project management model, and monitors projects in real-time through SAP/PLM.

Secote uses a strong matrix project management model, and monitors projects in real-time through SAP/PLM.

15 percent are Masters’ and above degree graduates.

15 percent are Masters’ and above degree graduates.

The Project Management team members all have PMP skills and speak fluent English.

The Project Management team members all have PMP skills and speak fluent English.

Secote’s R&D team is composed of elite professionals in the automation industry.

Secote applies international quality management tools, establishing detection systems in geometric parameters, measurement, mechanics, electromagnetism, acoustics, optics, and chemistry. Using barcode tracking processes within production, Secote identifies and maintains product quality control, and has ISO9001 Quality System Certification.